08.11.2022

Info

25th Anniversary

Time and tide wait for no man.

On October 1, 1997, the three of us rowed a boat into the open rough sea, and after spanning nearly a quarter of a century from 20th to 21st century, we have become a company specialized in barrier and decontamination technology with more than 140 people in Japan and more than 400 people, including joint ventures in China and Korea under the Airex brand.

We would like to express my deepest gratitude to all of you for your continuous support.

During this time, we started to imitate the barrier and decontamination technologies which started in Europe and the United States. But we have always added our own unique technology with our innate dislike of defeat, and we have transferred Japanese technology and spirit to Europe and the United States.

We will continue to do this with all our heart. We will go forward on a straight line on the road with the best isolator technology. We would like to ask you or your guidance and encouragement onward to the future.

President & CEO Koji Kawasaki

Airex Co., Ltd.

1. Let's take a moment to reflect on Airex's proprietary technology

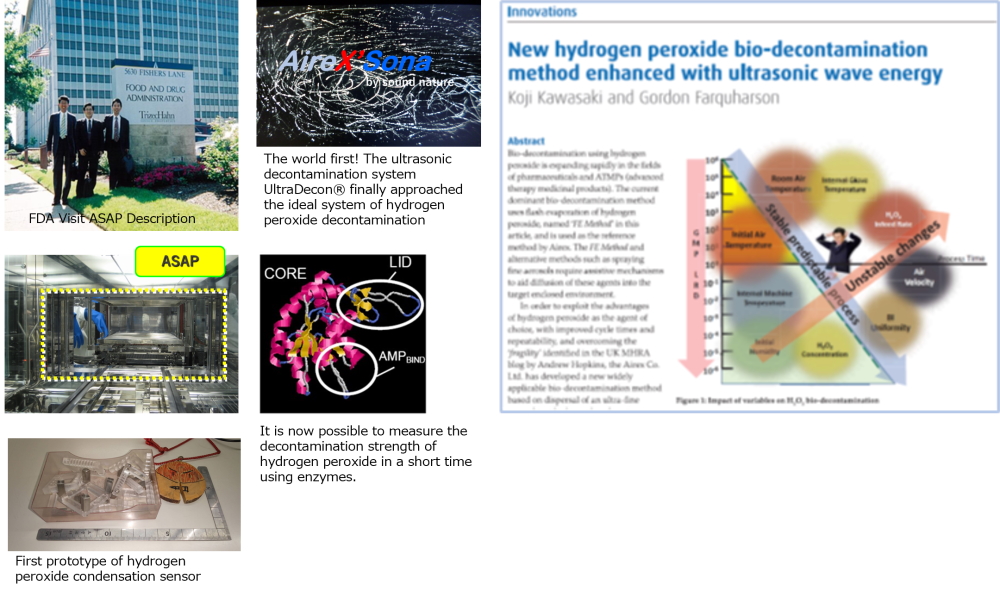

(1) There are various explanations for hydrogen peroxide decontamination, such as Dry, Wet, and Semi Dry. However, it has been found that condensation of invisible thicknesses of the layer, greatly affects decontamination. We have developed the SDM, a condensation sensor that companies around the world have tried but gave up, and are still using it to understand the complexity and important issues regarding gas decontamination.

(2) ASAP® (Air Sealed Aseptic Port) was evaluated (encouraged) by visiting the FDA in person. It has demonstrated the robustness in nearly 15 years of onsite operation. The Annex A concept used in ASAP® is regarded as a pioneer in the supply of Grade A air, that are now taken for granted.

(3) World's first ultrasonic hydrogen peroxide decontamination (UltraDecon® international brand name X'Sona®) was developed. The decontamination design space for temperature and humidity is large, there are no irregularities in D values for each material, and decontamination can be performed in a short time with very little hydrogen peroxide, and actual deployment can be started not only in Japan but also overseas.

The technology was presented last year in the British magazine CACAR with renowned UK renowned Mr. Gordon Farquharson.

This success was due to the use of EI (enzyme indicator) to search for decontamination intensity.

By using EI in conjunction with BI, the scientific support of the scientific QRM of hydrogen peroxide decontamination has greatly progressed.

2. Current status and future of Airex technology

Airex is now aiming to be the world-class and leading company in sterile, containment, BSL, decontamination and barrier systems. We are promoting not only research and development, but also in-house education as well.

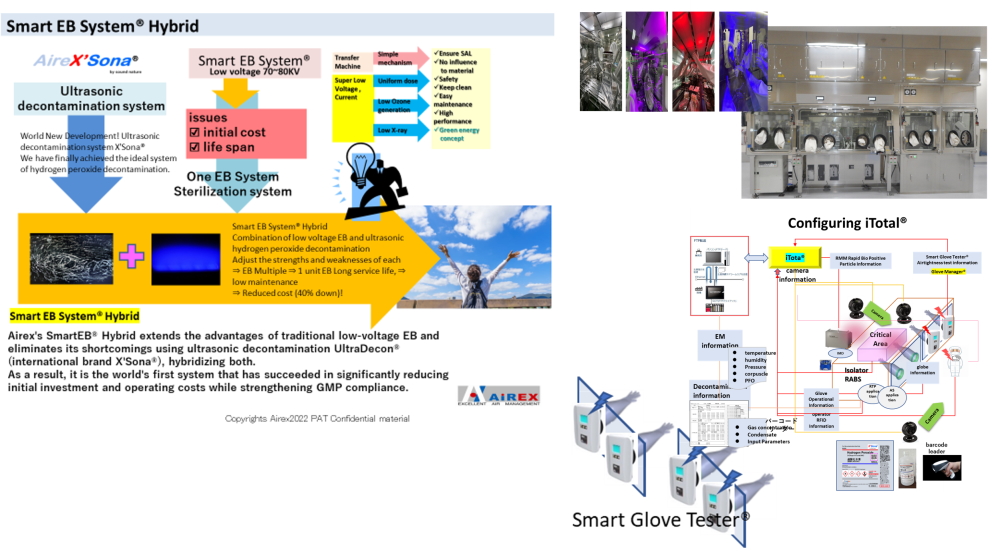

UltraDecon® (X'Sona®), is an ultrasonic decontamination technology for sterilization, that aims to achieve an ideal for scientific system in terms of hydrogen peroxide usage, cycle time, robustness of decontamination and validation. Airex believes that high-speed decontamination, continuous decontamination, and Smart EB®Hybrid, (a system combined with EB electron beams), are the world's first technology that Airex can be proud of.

Aseptic + containment measures have already accumulated many achievements.

The ΔCCC® isolator for containment of highly active drugs can be a culminated over a period of 25 years of results. Listening to feedback is the best way to keep pace with customer demand and fulfill our customers short- and long-term expectations, and

Airex will focus on improving our position.

In addition, iTotal®, which integrates various RMM technologies such as BBCheck®, Smart Glove Tester®, etc., which accumulate and systematize management information for sterile areas, can further promote the understanding and visualization of DI (Data Integrity), and CCS (Contamination Control Strategy), which has become clear with the revised PIC/s Annex1.

Like the X'Sona CPF concept, Airex would like to promote the application of this concept to CPF for ARMP, and improve the degree of perfection and clarify the effect.

Of course, these technologies are also effective for retrofitting (modernization) of equipment Ultra Fit™, and Airex will widely promote CCS support in line with the PIC/s concept, regardless of whether it is newly established or have already been installed.

Airex will also promote efficient process using O'Hara continuous tablet coating machine and Actini continuous waste treatment equipment for biologics such as vaccines.

3. The Future of Airex

We will continue to improve our various skills and follow the isolator path based on the following five points.

1. Airex will proceed in accordance with the spirit of GMP in deep mind.

2. Respond to customers faster and more accurately. Airex will prepare a dedicated system and personnel for that

purpose.

3. Airex will constantly explore and build the latest technologies that are conscious of the SDGs and carbon neutral.

4. Data Integrity (DI) enhancements. For this purpose, Airex will promote visualization technology, including RMM, and

response to customers' DX concepts.

5. To the world

Airex would like to ask for your continuous guidance and encouragement

President & CEO

Koji Kawasaki

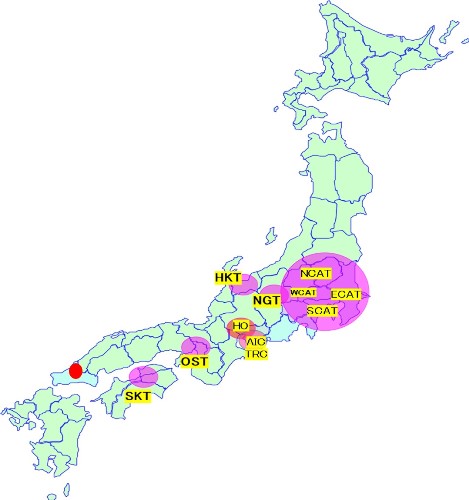

Airex is expanding the technical sales service offices nationwide.

In response to customers, Airex has begun to expand and maintain its nationwide offices in consideration of the current situation of COVID19 and its aftermath.

This expansion is for fast technical, sales, validation and maintenance for customers.

In addition to our current head office (Nagoya) and technical centers TRC, AIC (Tokai City), Marugame (SKT), and Ueda (NGT), we opened new technical offices in NCAT (Kumagaya City), SCAT (Fujisawa City), and Toyama (HKT) this year.

Next year, Airex plan to open WCAT (Tachikawa City), ECAT (Chiba City), and WJT Shinyamaguchi.