Electron beam sterlization

Airex Smart EB®

Airex Smart EB® system run very low voltage sterilization acheiving just only 25 kGy radiation energy for the surface. Airex Smart EB® system guarantees the sterile transfer of syringe, vial tubs and other aplications into an aseptic filling line isolator. The system is specially designed to facilitate continuous process with a high throughput.

Benefits

- * High quality design

- * Only 25KGy achieve high sterilization assurance level(Log 6)

- * Low voltage system, only 70 KV

- * Continuous high speed up to 6 tubs per minute

- * Low ozon generation

- * ISO 5 Unidirectional airflow

- * Integrated H2O2 (hydrogen peroxide) decontamination

- * A continuous aseptic transfer of pre-sterilised tubs into high speed filling lines which is quick, safe and simple

- * cGMP-/FDA-compliant design

- * Full qualification services (FAT,IQ,OQ)

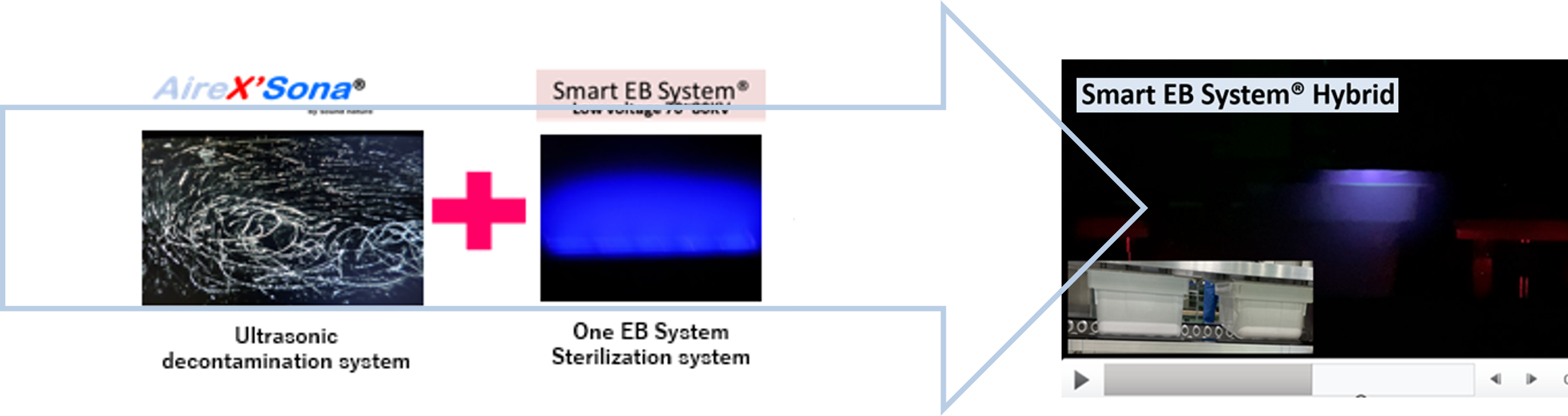

Airex Smart EB® Hybrid

Completion of Smart EB® Hybrid

Airex has completed the Smart EB®Hybrid, which combines the ultrasonic hydrogen peroxide decontamination method X'Sona® with a low-voltage electron beam. It is the world's first system that can continuously sterilize and decontaminate syringe tabs with a single EB.

1. Background

Prefilled syringe injection is increasingly being adopted all over the world, especially for convenience.

However, bringing a sterile syringe (tab) into a grade A filling aseptic area is not easy.

Appropriate methods cannot be found due to (1) capital investment and (2) the penetration of decontamination agents, which is one of the worries of the problem.

In the early days of PFS, the most robust EB electron beam sterilization method was extended on GMP, but due to initial investment and maintenance (EB life), etc., it is being replaced by the NTT method (No Touch Transfer), which opens a simple bag and inserts tabs from the mousehole. However, it must be said that it is remained much concerns such as dust generation at the time of cutting, difficulty of cutting, and difficulty in controlling the airflow required by GMP.

2. That's where the Smart EB® Hybrid is developed.

3. Technology Essentials

The outer surface of the plastic container of the syringe tab is continuously decontaminated by ultrasonic hydrogen peroxide method(UDM). The upper Tyvek® (gas permeable membrane) performs EB electron beam sterilization after UDM.

This method prevents the penetration of hydrogen peroxide into the Tab and ensures decontamination and sterilization strength of 6LRD and 25Kgy.